Pumper

Our primary appliance for all structure fires and incidents.

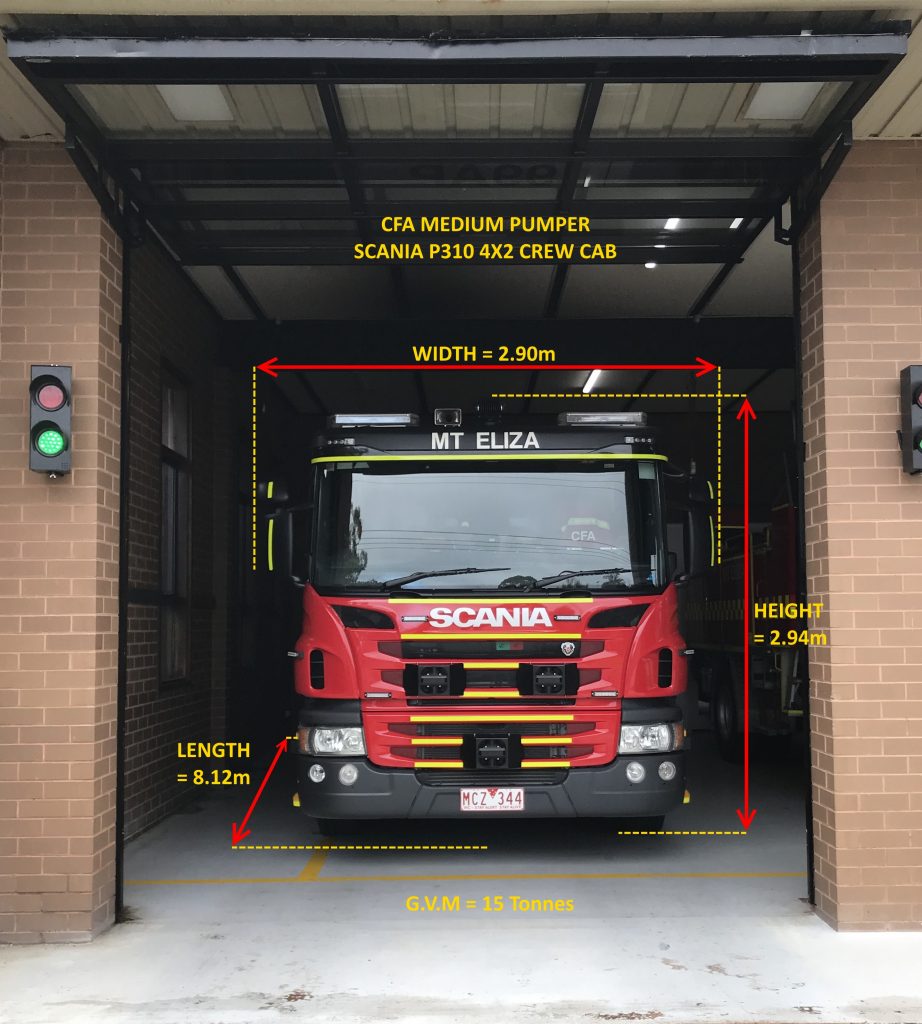

Medium Pumper – Scania P310

Cab Chassis: Scania P310 Euro 5 (4×2) Crew Cab Chassis

GVM: 15,500 kg

Dimensions: Length 8.10 m, Height 2.96 m

Wheelbase: 4,300 mm

Crew: 5 person

Engine: Turbocharged, Intercooled 9.30 L, 5 Cylinder Diesel

Nett Power: 230 kW @ 1,900 RPM

Nett Torque: 1,550 Nm @ 1,000 – 1,200 RPM

Transmission: 6 Speed Automatic Incorporating Hydraulic Retardation

Main Pump: Rear Mounted Single Stage Pressure Pump Driven by Transmission Mounted Power Take Off (PTO)

Pump Duty: Godiva P1 4010 single stage centrifugal pump 4,000 L/m @ 700 kPa.

Primer Pump: Automatic

Water Tank: 2,500 L Polypropylene

Foam Tanks: Class “A” Foam Tank (50 L), Class “B” Foam Tank (300 L)

Foam System: Direct Injection Class “A” and “B” Foam System

Body:

- Aluminium Extruded Frame System Based on a Fully Galvanised Steel Sub-Frame

- Stainless Steel Plumbing Arrangement

- 3 Stowage Lockers on Each Side of the Body

- Rear Hose Lockers with Flaked Hose Bins and Adaptors

- Fully Enclosed Rear Pump Panel with Side Delivery Discharges

- 2 x Electrically Powered Dead Hose Reels

- 6 x 24V LED Pneumatic Telescopic Light Mast

- Full LED Body Lighting

- Red/Blue LED Emergency Lighting

- Air Horn

- Can Bus Multiplexing

- 7.8 m Double Extension Aluminium Ladder

Stowage Equipment

- Breathing Apparatus

- Protective Gear

- Foam Equipment

- Adaptors

- Branches

- Welfare

- Salvage

- PPV Fan

- Battery Lighting

- Ground Monitor

- Stowage Equipment

- Hose

- 16 x Ø65 mm Storz

- 7 x Ø38 mm

- 4 x Ø125 mm Heliflex Suction

Min. License. Class: Medium Rigid

Tanker

Our primary appliance for bushfires.

Medium Tanker – Hino Ranger GT Series 500 1322 (4×4) Crew Cab Chassis

Hino GT Series 500 1322 4×4 Crew Cab Chassis

- Engine – 158 kW (212HP) turbo-charged, intercooled, 6 cylinder diesel engine

- Six (6) speed (5 forward & 1 reverse) automatic transmission

- Seating for five (5) crew – 2 in the front & 3 in the rear (all seats fitted with lap/sash seatbelts)

- 200L fuel tank

- 11R22.5” Bridgestone M857 tubeless tyres

- Air conditioning, electric windows, fog lights, reversing camera

- Air over hydraulic braking system (incl. ABS)

- Aluminium bull bar & electric cab tilt

- Cabin internal support bar (B post stiffener)

- Thermaguard SUPERTHERMTM radiant heat protection curtains fitted to all cabin windows

- Vehicle/crew spray protection system (with 2 position switch activation – cabin and ROPS)

Firefighting Body & Plumbing

- Polyethylene rota molded water tank – 2,350 litres capacity (including 650 litres for a vehicle/crew spray protection system) c/w baffle bones for surge protection.

- Fabricated steel/aluminum tray frame & external roll over protection bar

- 2 Staged GAAM Mk 300D pump/22kW Hatz 2L41C diesel engine (Output: 900 l/min @ 700 kPa)

- Electric priming pump

- Water cooled diesel driven Ultra High Pressure System (UHPS) (nom. 25l/min @ 100 bar) connected to 1 x Ø12mm 60m electric rewind hose reel fitted with aspirating fog gun nozzle. Note: UHPS nearside rear mounted on a slide out frame (for maintenance access). UHPS fitted with stand alone inductive foam system

- Major plumbing including:

- 1 x TFT electric bull bar mounted monitor fitted with adjustable nozzle (nom. min. 100-450 l/min capacity) c/w remote “in cabin” joystick controller

- Rear deliveries – 1 x Ø38mm (external lug) and 2 x Ø65mm (Storz)

- NS/OS forward below tray deliveries (per side) – 1 x Ø38mm (external lug)

- 1 x electric rewind live hose reel c/w 20m Ø25mm hose (mounted above tray NS rear)

- Rear below tray hydrant boost – 1 x Ø65mm (Storz)

- Hard suction c/w permanently connected 9m of Ø75mm “wire whipped” suction hose fitted in NS rear undertray locker (NS deployed)

- NS undertray Ø65mm tank fill (Storz)

- Vehicle control system including:

- CANBUS multiplexing

- Cabin forward console – pump & emergency response system control

- Deck console – pump control

- Rear console – pump controls and tank/pump indication

- ROPS mounted “Crew Protection Drop Down Awning” with StormKing Mountain® radiant heat protection curtain

- Quenchmaster CF700CFA inductive Class “A” foam system c/w slide-out drum rack for 2 x 20 litre Carboys (OS undertray) feeding all deliveries & monitors

- Note: UHPS Class “A” foam capable via dedicated inductive system

- Aluminium fabricated above tray lockering/stowage (comparable to 2.4C ) including:

- NS1 – optional BA – gas strut top hinged

- NS2 – hose, adaptors, chainsaw – gas strut top hinged

- OS1 (slide out for pump bay maintenance access) – salvage gear

- NS Cabin/Body – PPE/Miscellaneous gear

- Capacity to stow 4 x Ø64mm & 5 x Ø38mm hose (incl. dead hose reel)

- Little Giant 10103 MT22 Multi-function ladder (min. 5.8m extended length) OS mounted between the cabin and body on a slide out frame

- Dead hose reel. (OS rear under tray)

- 20L fresh water tank

- NS undertray welfare locker c/w 25L removable esky – sufficient for 24 x 600ml water bottles

FCV – Field Command Vehicle

Our Brigade purchased Toyota Land Cruiser which is used as a command vehicle at Strike Teams as well as for additional crew support for local incidents.

FCV – Toyota Land Cruiser